Powder:±2%

Delivery Time:

Shipping:

Contact customer service to negotiate shipping details, Enjoy On-time Dispatch Guarantee

After-sales Service:1. Online service: samples, technical specifications, operation manuals, spare parts purchase. 2. Video service: application guidance, troubleshooting and maintenance guidance. 3. Overseas service: MachPlaza has a complete global after-sales service team. Please note that if there is no clear after-sales liability clause in the sales contract, we will charge the necessary service fees.

Feature

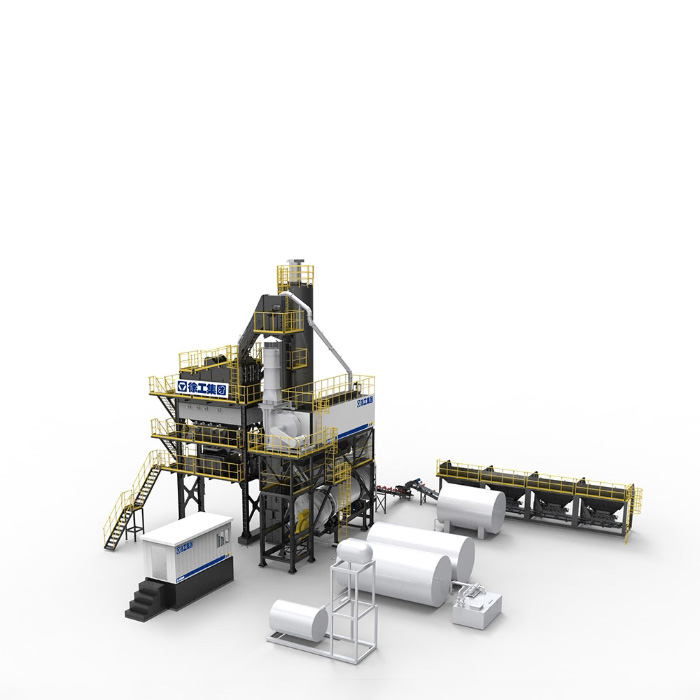

The Shantui SjWBZ700-3S Stabilized Soil Mixing Plant is an advanced, high-capacity solution for producing stabilized soil mixtures, which are critical for roadbed construction and other large-scale infrastructure projects. With a mixing capacity of 700 tonnes per hour, the plant can efficiently handle large volumes of material and is ideal for building highways, airports and railways, where stable, compacted foundations are essential.

The mixing plant uses advanced technology to ensure precise and consistent soil stability. Its twin-shaft continuous mixer ensures thorough and even mixing of soil, lime, cement and other binders. This ensures the production of a homogeneous stabilized soil mixture that meets the strength and durability requirements required for long-lasting infrastructure. The plant’s high mixing efficiency minimizes waste, thereby reducing material costs.

The SjWBZ700-3S features an automatic control system that allows operators to accurately monitor and adjust production parameters through an easy-to-use interface. The PLC control system automates the entire process from ingredient feeding and batching to mixing and unloading, ensuring consistent production quality while reducing labor costs and human errors. The system can store multiple mix designs and can be quickly adjusted to different project requirements.

Parameter

| Rated productivity | 700t/h |

| Powder | ±2% |

| Water | ±1% |

| Total installed power | 243kW |

| Maximum single power | 37kW |

| Area | 5X12m² |

| Allowable aggregate size | Less than 50mmmm |

Request a Quote

Model Comparison

Brand

Brand

Type

A

AOLITE

B

BEIBEN

BOMAG

BINZUAN

C

CHENGGONG

D

DINGLI

DOOSAN

DEVELON

E

ENSIGN

F

FAW

FOTON

H

HELI

SHACMAN

HONGYAN

HYUNDAI

J

JONYONG

JAC

JINGONG

L

LUYU

LISHIDE

LONKING

LIUGONG

LOVOL

S

SINOTRUK

SEM

SINOMACH

SUNWARD

SDLG

SANY

SHANTUI

X

XINIU

XGMA

XCMG

Y

YUCHAI

Z

ZOOMLION