Asphalt:0.2%

Delivery Time:

Shipping:

Contact customer service to negotiate shipping details, Enjoy On-time Dispatch Guarantee

After-sales Service:1. Online service: samples, technical specifications, operation manuals, spare parts purchase. 2. Video service: application guidance, troubleshooting and maintenance guidance. 3. Overseas service: MachPlaza has a complete global after-sales service team. Please note that if there is no clear after-sales liability clause in the sales contract, we will charge the necessary service fees.

Feature

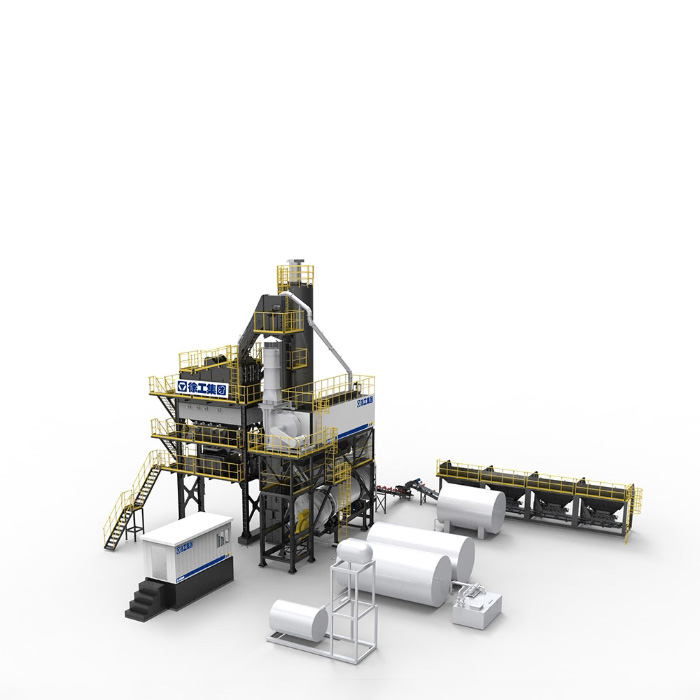

The XCMG XAP405H Asphalt Mixing Equipment offers a variety of advantages that make it a top choice for large-scale asphalt production, especially for road construction and infrastructure projects. Here are the key advantages:

1. High Production Capacity:

- With a production capacity of up to 405 tons per hour, the XAP405H is ideal for large-scale projects such as highways, bridges, airports, and urban roads. Its high output allows for continuous asphalt supply, reducing project timelines and increasing efficiency.

2. Advanced Mixing Technology:

- The batch-type mixing process ensures precise control over the mix proportions, resulting in high-quality, consistent asphalt mixtures. This technology provides flexibility for adjusting the mix based on specific project requirements, ensuring superior asphalt quality.

3. Energy Efficiency:

- The XAP405H incorporates energy-saving systems, minimizing fuel consumption and reducing overall operational costs. This is particularly important for projects that require long-term asphalt production, offering significant cost savings in the long run.

4. Environmentally Friendly:

- Equipped with a state-of-the-art dust collection system, the XAP405H reduces emissions and air pollution, meeting stringent environmental regulations. Its environmentally friendly design helps construction companies maintain compliance while reducing their ecological footprint.

5. User-friendly Control System:

- The equipment features a fully automated control system that simplifies operations and increases precision. Real-time monitoring and adjustments during production help maintain consistent quality, while the user-friendly interface reduces the need for skilled labor, optimizing both performance and efficiency.

6. Durability and Reliability:

- Constructed with high-strength materials, the XAP405H is designed to withstand the rigors of continuous operation in harsh working conditions. Its robust design ensures long-term reliability, reducing downtime for repairs and maintenance, which is critical for large, time-sensitive projects.

7. Modular Design for Flexibility:

- The modular design allows for easy installation, disassembly, and transportation, making the equipment adaptable to different project sites. This flexibility reduces setup times and makes it easier to move the equipment between locations as needed.

8. Cost-effective Operation:

- Factory-direct pricing makes the XAP405H a cost-effective solution for companies looking to maximize value without compromising on quality. Additionally, the equipment’s low operational and maintenance costs contribute to long-term savings.

9. Precision and Quality Control:

- The automated system ensures precise control over the production process, enabling adjustments based on the specific needs of each project. This results in higher-quality asphalt mixtures, reducing waste and ensuring consistency across large volumes.

10. Versatility for Various Projects:

- The XAP405H can produce a wide range of asphalt mixtures, making it versatile for different types of construction, from highways to urban road networks. Its flexibility in handling different asphalt grades ensures adaptability across various project requirements.

Parameter

| Rated productivity | 400t/h |

| Mixing capacity | 5500kg/patch |

| Asphalt | 0.2% |

| Powder | 0.3% |

| Aggregate | 0.3% |

| Aggregate grades | / |

| Fuel consumption | 6.5kg/t |

| Dust emission concentration | 40mg/Nm³ |

| Asphalt fume | 30mg/m³ |

| Nitric oxide | 200mg/m³ |

| Sulfur dioxide | 200mg/m³ |

| Carbon monoxide | 1000mg/m³ |

| Blackness of exhaustion (Ringelman class) | ≤I |

| Total power | 1096kW |

| Maximum single power | 250kW |

| Floor area | 2624(64×41)m² |

| Thermal oilfurnace heating capacity | / |

| Optional finished product bin volume | 55m |

Request a Quote

Model Comparison

Brand

Brand

Type

A

AOLITE

B

BEIBEN

BOMAG

BINZUAN

C

CHENGGONG

D

DINGLI

DOOSAN

DEVELON

E

ENSIGN

F

FAW

FOTON

H

HELI

SHACMAN

HONGYAN

HYUNDAI

J

JONYONG

JAC

JINGONG

L

LUYU

LISHIDE

LONKING

LIUGONG

LOVOL

S

SINOTRUK

SEM

SINOMACH

SUNWARD

SDLG

SANY

SHANTUI

X

XINIU

XGMA

XCMG

Y

YUCHAI

Z

ZOOMLION